Guide to Applying Acrylic Industrial Paints from Independent Paint Supplies

Key Takeaways

- Acrylic industrial paints are prized for their durability and weather resistance.

- Proper surface preparation, including cleaning, sanding, and priming, is crucial for paint adhesion.

- Choosing the right tools, such as brushes, rollers, or spray equipment, affects the finish quality.

- Techniques for mixing, applying, and drying acrylic paints are key for a professional result.

- Maintenance and protective measures extend the lifespan of an acrylic paint job.

Unlocking the Power of Acrylic Industrial Paints

When it comes to industrial paint jobs, the choice of paint can make or break the success of your project. Acrylic industrial paints are a go-to for professionals seeking a blend of durability, aesthetic appeal, and long-lasting protection. But how do you harness the full potential of these paints? Let’s dive in and get those surfaces covered with confidence.

Acrylic’s Edge in Industrial Durability

What sets acrylic paints apart in the industrial realm? It’s their incredible resilience. These paints form a hard, protective shell that stands up to the rigors of industrial environments. Think about the beating that machinery, tanks, and outdoor structures take from the elements and daily use. Acrylic paints shield them from rust, UV rays, and even chemical exposure. This is why, when durability is a priority, acrylic paints are often at the top of the list.

Versatility Across Surfaces

Whether you’re painting a smooth metal surface or a rough outdoor wall, acrylic paints are up to the task. They adhere well to a variety of substrates, which means you’re not limited in what you can protect and beautify. But remember, the key to making the most of this versatility lies in the preparation and application. Let’s explore how to lay the groundwork for a top-notch paint job.

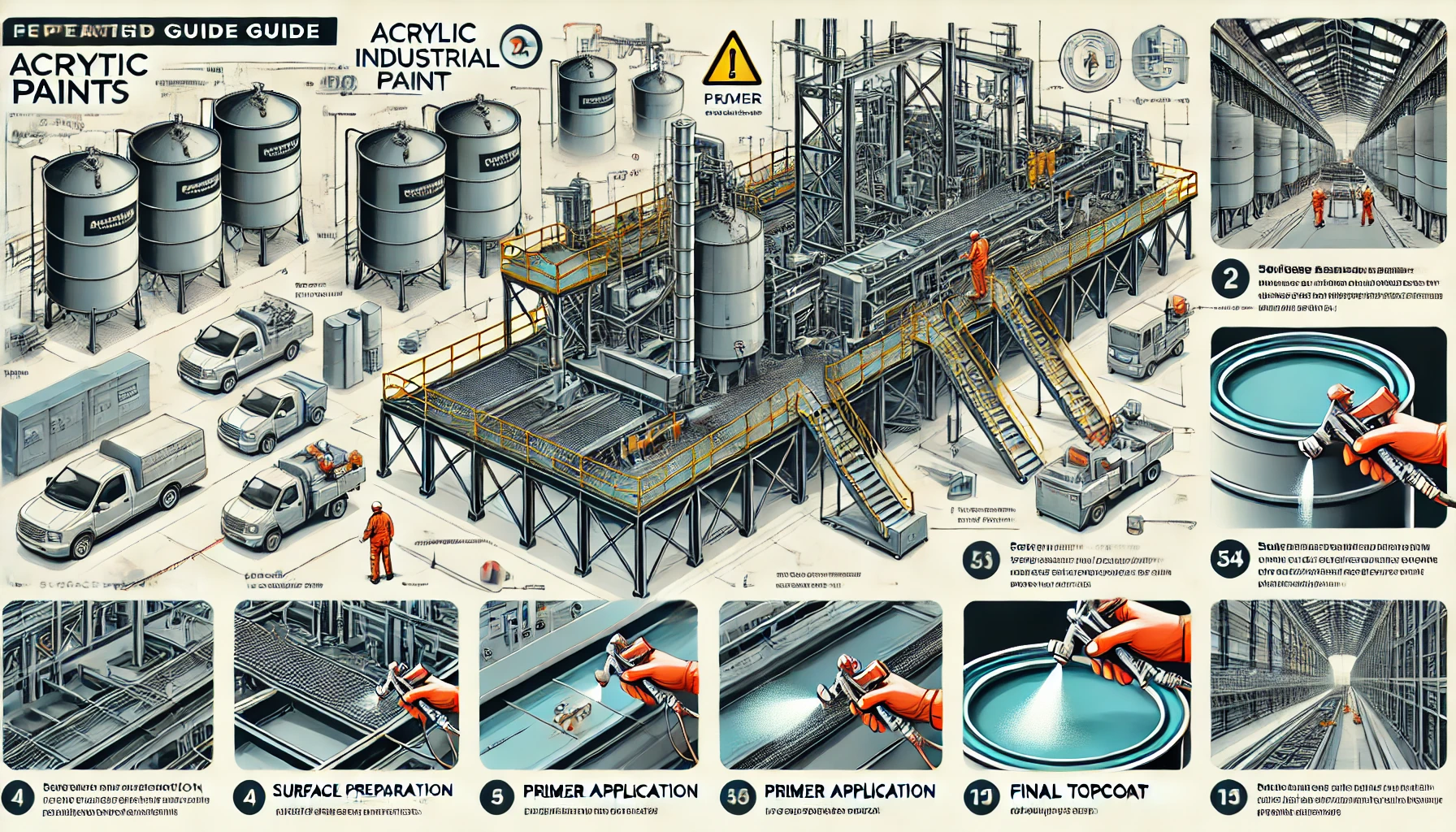

Step-by-Step Mastery of Acrylic Application

Applying acrylic industrial paints isn’t just about slapping on a coat of color. It’s an art and a science that requires attention to detail at every step. Follow these guidelines to ensure your work not only looks great but also stands the test of time.

Surface Preparation Essentials

Before a single drop of paint touches the surface, you’ve got to prep it. This is where many paint jobs fail, so don’t skip this part!

First off, we’re dealing with industrial surfaces, which often means they’re not in pristine condition. You might be facing grime, rust, or old paint. These contaminants are your enemy because they prevent paint from sticking properly. Therefore, you’ll need to get the surface clean and smooth.

Cleaning Protocols

For cleaning, you’ll want to remove any dirt, oil, or grease. This can often be done with a simple degreaser or soapy water for less grimy areas. For outdoor surfaces, pressure washing is a quick way to blast away unwanted layers. Just ensure the surface is completely dry before moving on to the next step.

Sanding Techniques

Once clean, it’s time to sand. Sanding creates a rougher surface for the paint to grip. For metal surfaces, you might need a wire brush or a sander with appropriate grit sandpaper. The goal is not to polish but to scuff, creating a texture that paint can cling to.

Priming Strategies

After sanding, a good primer sets the stage for paint adhesion. It’s like the glue that binds your paint to the surface. Choose a primer that’s compatible with acrylic paint and the material you’re working with. Apply it evenly and let it fully dry as per the manufacturer’s instructions.

Tool Selection for Acrylic Painting

The tools you choose can be the difference between an amateur and a professional finish. Let’s consider the options.

Brushes Versus Rollers

Brushes are great for detail work and small areas. They allow for precision but can be slower for larger surfaces. Rollers, on the other hand, cover more area faster and are ideal for flat, expansive surfaces. The finish you’re aiming for and the size of your project will dictate the best choice.

Acrylic Paint Application

Once your surface is prepped and primed, it’s time to move on to the main event – applying the acrylic paint. But before you pop open that paint can, there’s a bit more prep work to do. Let’s make sure your paint is ready to go on smoothly and stay on for a long time.

Mixing and Thinning Practices

Acrylic paints usually come ready to apply, but sometimes they might need a bit of tweaking. If the paint is too thick, it won’t spread well, and you’ll have a tough time getting an even coat. On the flip side, too thin and it won’t cover well, and you’ll be doing more coats than necessary. Follow the manufacturer’s instructions for mixing and thinning. If thinning is needed, use the correct thinner and mix well until you get a consistent, workable viscosity.

Techniques for Even Coating

For a professional-looking job, an even coat is key. When using a brush, apply paint with smooth, long strokes. If you’re rolling, use a W or M pattern for large surfaces to ensure coverage without missed spots or overlaps. When spraying, keep the nozzle a consistent distance from the surface and move in a steady, controlled motion. It’s better to do a couple of light coats than one heavy one, as this prevents drips and gives a more uniform finish.

Drying Times and Conditions

Patience is a virtue, especially when it comes to letting paint dry. Rush it, and you might end up with a sticky mess that attracts dirt or shows fingerprints. Check the paint can for the recommended drying time between coats. Conditions like humidity and temperature can affect drying times, so adjust your expectations accordingly. A well-ventilated area is best to help the paint cure properly.

| Step | Process | Tips |

|---|---|---|

| 1. Surface Preparation | Clean and sand the surface | Remove dirt, grease, and loose paint; sand for better adhesion |

| 2. Priming | Apply appropriate primer | Use primer compatible with acrylic paint; allow to dry completely |

| 3. Mixing | Stir paint thoroughly | Ensure even color distribution; thin if necessary (5-10% water) |

| 4. Application Method | Choose brush, roller, or spray | Select based on surface area and desired finish |

| 5. First Coat | Apply thin, even layer | Work in one direction; avoid overloading |

| 6. Drying Time | Allow to dry completely | Follow manufacturer’s recommendations (typically 2-4 hours) |

| 7. Second Coat | Apply additional thin layer | Apply perpendicular to first coat for even coverage |

| 8. Finishing | Inspect and touch up if needed | Address any missed spots or imperfections |

| 9. Curing | Allow paint to fully cure | Typically 24-48 hours for light use, 7 days for full cure |

| 10. Clean-up | Clean tools with water | Clean immediately after use for best results |

Guide to Applying Acrylic Industrial Paints

Customising Your Acrylic Coat

Now, let’s talk about making that paint job really yours. Customizing your acrylic coat isn’t just about picking a colour; it’s about choosing the right type of paint for the job and the conditions it will face.

Choosing the Right Paint for Your Project

Not all acrylic paints are created equal. Some are formulated for higher heat resistance, while others are made to withstand chemical exposure. Consider the environment your painted surface will live in. Will it be outdoors, exposed to the sun and rain? Or will it be indoors, where it might come into contact with oils or solvents? Answering these questions will guide you in selecting the perfect paint.

- Heat resistance for high-temperature areas.

- UV resistance for outdoor exposure.

- Chemical resistance for factories or garages.

Once you’ve considered the functional requirements, you can think about aesthetics. What finish do you want? Glossy, matte, or something in between? Each has its own advantages and will affect the look and feel of the finished project.

Color and Finish Selection

Color can be about more than personal preference. In an industrial setting, colors can serve as safety indicators or to designate different areas. Choose a color that meets your functional and aesthetic needs. For finishes, glossier paints are easier to clean and can make colors pop, while matte finishes might be better at hiding surface imperfections.

Considering Environmental Factors

Environmental considerations are crucial. If you’re working on an outdoor project, you’ll need a paint that can handle whatever Mother Nature throws at it. This means looking for paints that are specifically formulated to be weatherproof. If your project is in an area with strict environmental regulations, look for low-VOC or VOC-free options to keep air quality in check.

Advanced Acrylic Techniques

Once you’ve got the basics down, you can start to play with more advanced techniques to really elevate your paint job.

Example: For a project requiring extreme durability, you might apply a base coat, a fiber-reinforced mid-layer, and a topcoat with UV protection. This layering not only increases the lifespan of the paint job but also adds depth to the finish.

Layering for Durability

Layering your paint can enhance durability and impact resistance. Start with a solid base coat, and then add specialized layers depending on the needs of your project. For instance, a rust-inhibiting layer is perfect for metal surfaces that will be exposed to moisture.

Special Effects with Textures

Texture can add a whole new dimension to your paint job. With acrylics, you can create effects like stippling or sand finishes, which not only look great but can also provide extra grip on floors or handrails. Experiment with different tools and techniques to achieve the texture you want.

- Stippling for a textured, non-slip surface.

- Sanding finishes for a smooth, refined look.

- Adding aggregates to paint for extra grip and durability.

Remember, the key to a successful industrial paint job is in the details. Take the time to understand the materials you’re working with, choose the right paint and tools, and apply with care. Your work will not only look better but will also last longer, saving time and money in the long run.

Prolonging the Life of Your Acrylic Paint Job

Once you’ve applied your acrylic industrial paint, the journey doesn’t end there. To keep that finish looking sharp and performing well, you need to take steps to protect it. Think of it as setting up a shield against the barrage of environmental factors and wear-and-tear that it will inevitably face.

Protective Measures for Longevity

Sealing your acrylic paint job with a topcoat is like putting on a raincoat before a storm. It’s an extra layer of defense that can make all the difference. The right topcoat can provide UV protection, resist chemicals, and make cleaning easier. It’s an investment that pays off by extending the life of your paint job significantly.

Sealing and Topcoats

When selecting a topcoat, consider the conditions your painted surface will be exposed to. For outdoor applications, a topcoat with UV protection is essential to prevent fading and degradation. For industrial settings, a topcoat that can resist oils, chemicals, and abrasions might be necessary. Apply the topcoat according to the manufacturer’s instructions for the best results.

Mitigating Environmental Damage

Environmental damage comes in many forms – UV rays, rain, extreme temperatures, and pollutants can all take a toll on your paint job. By choosing acrylic paints with built-in weatherproofing and applying them correctly, you can mitigate a lot of this damage. Regular inspections and prompt touch-ups can also help keep the environment from wearing down your paint job.

Maintenance and Touch-Up Strategies

Maintenance is key to keeping your acrylic paint looking its best. With a few simple strategies, you can maintain the integrity and appearance of your paint job for years to come.

Cleaning Tips

Keeping your painted surfaces clean not only makes them look good but also prevents buildup that can damage the paint over time. For most acrylic industrial paints, a gentle soap and water solution is sufficient for cleaning. Avoid harsh chemicals and scrubbing pads that can scratch or wear down the finish.

- Use a soft cloth or sponge for cleaning.

- Rinse with clean water after washing to remove any soap residue.

- Clean spills and stains promptly to prevent them from setting.

Regular cleaning also gives you the opportunity to inspect the paint for any signs of wear or damage. Addressing these issues early can prevent larger problems down the line.

Identifying and Fixing Wear

Spotting a small chip or crack early can save you a lot of trouble. If you catch it in time, a simple touch-up can fix the problem. Ignore it, and you could be looking at a full repaint.

When you find areas that need attention, clean the area thoroughly and sand it lightly to help the new paint adhere. Then, apply a matching acrylic paint to the spot. If you’ve used a topcoat, don’t forget to reapply it over the touch-up to seal it in.

Frequently Asked Questions (FAQ)

Can Acrylic Paints Be Used on Outdoor Structures?

Yes, acrylic paints are an excellent choice for outdoor structures due to their durability and resistance to weathering. Just make sure to choose a paint formulated for outdoor use and apply a suitable topcoat for additional protection.

What Are the Main Advantages of Choosing Acrylic Over Other Industrial Paints?

Acrylic paints dry quickly, offer excellent color retention, and resist the effects of sunlight and harsh weather conditions. They’re also generally easier to work with and clean up than oil-based paints.

How Long Should Acrylic Paint Dry Between Coats?

Drying times can vary based on the product, but as a general rule, allow at least 1-2 hours for acrylic paint to dry to the touch before applying another coat. Always check the manufacturer’s recommendations, as some formulations may require longer drying times.

Are There Any Special Considerations When Applying Acrylic Paint in Cold Weather?

Cold weather can affect the drying time and adhesion of acrylic paint. It’s best to apply it in temperatures above 50°F (10°C). If you must paint in colder conditions, look for products specifically formulated for low temperatures and follow the manufacturer’s instructions closely.

How Do You Prepare a Rusty Metal Surface for Acrylic Paint?

For a rusty metal surface, you’ll need to remove as much rust as possible using a wire brush or sandpaper. Then, apply a rust-inhibiting primer before your acrylic paint. This will help prevent further rust and ensure better paint adhesion.